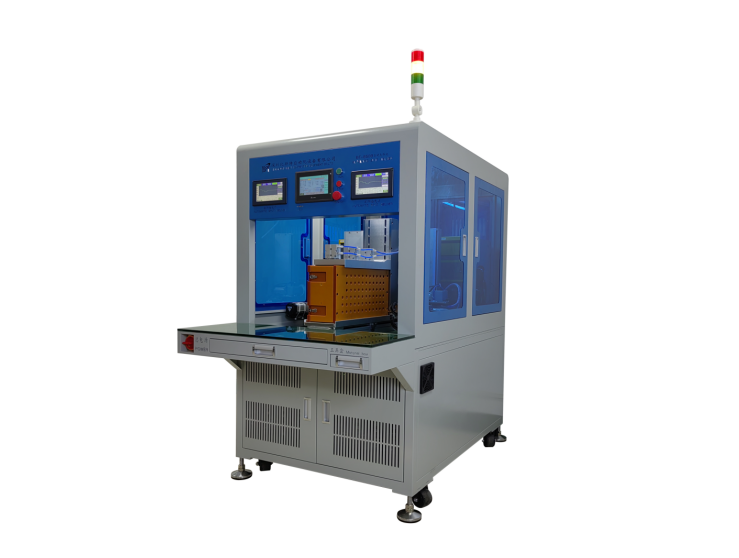

圆柱锂电池自动点焊机

产品特点(Product characteristics):

自动化焊接,焊点均匀,一致性良好,提高合格率实时焊接电流监控,虚焊或炸火报警自动停机

▶可选择点焊规范焊接(正负极可设置不同电流)

▶点焊坐标参数可采用U盘导入参数

▶运行机构采用伺服电机配合线型模组,精准定位

▶可设置点焊规范焊接(正负极分别使用不同电流焊接)

▶可设置同一电芯正极点焊,负极不点焊

▶Automatic welding, uniform solder joints, good consistency, improve the pass rate

▶Real-time monitoring of welding current, automatic stop of false welding or explosive fire alarm

▶Optional spot welding specification welding (positive and negative pole can set different current)

▶The coordinate parameters of spot welding can be imported by U Disk

▶The running mechanism adopts Servo Motor and linear module, and the positioning is precise

▶Spot welding specification can be set (positive and negative electrodes are welded with different current)

▶The same core can be set for positive pole spot welding, negative pole non-spot welding

1、主要功能:圆柱电芯的组合式双面自动化焊接

Main function:Auto double-sided welding of cylindrical battery

2、设备功率(Power) :3KW ,220V,50HZ

3、使用气压:0.4-0.8Mpa,使用气源时必须有过滤装置,确保

气流无水无杂质。

Air pressure:0.4-0.8Mpa, Air source must be used when there is a filter device to ensure that the flow of water-free impurities.

4、适应范围:动力电池的串并组合,多并多串组合电动工具电池,扭扭车电池(1个模具点焊6组),储能电池包,电动单车电池等

Adaptive range: Power Battery series-parallel combination of batteries, multi-parallel multi-series combination, electric tool battery, torsion car battery (1 die spot welding 6 groups) , energy storage battery pack, Electric Bicycle Battery, etc.

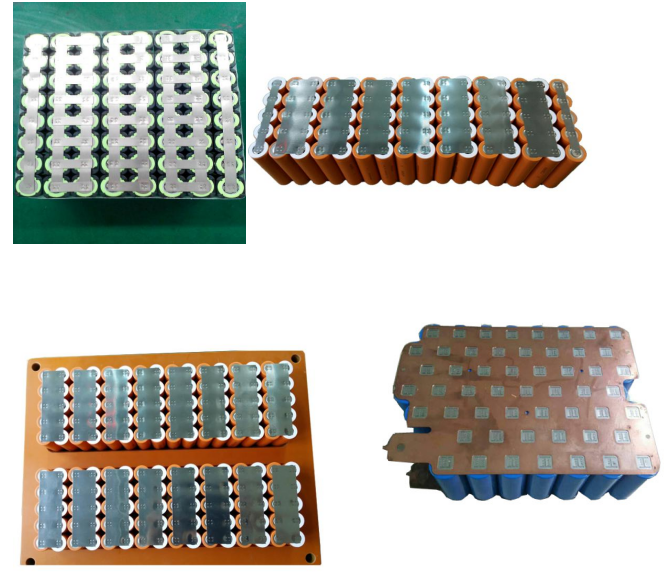

适合电芯(battery range):14430/14500/18500/18650/21700

26650/26700/32050/32700

5、最大行程:X axis:200-600mm ; Y axis:200-400mm

6、适合点焊针:进口直径4-4*6平头焊针(凸点焊接使用)

进口直径1.7*100MM(焊点点焊)

Suitable for spot welding:

Imported 4-4 * 6 flat head Pin (for projection welding)

Inlet diameter 1.7 * 100MM (spot welding)

7、适合镍片宽度:成型镍片

Suitable for nickel sheet width : Shaped nickel sheet

8、可定制点焊模具前进后出型(适合自动生产线使用)

Can Be customized spot welding die forward and backward type (suitable for automatic production line)

9、可定制自动打磨焊针功能

The function of auto-grinding and welding needle can be customized

10、适合镍片厚度(Nickel sheet thickness):

0.1MM---0.2MM(0.15—0.2MM厚度镍片需开槽)

(0.15-0.2MM thickness nickel sheet needs to be slotted)

凸点焊镍片(Bump welding nickel sheet):0.21—0.4MM

11、生产效率(Efficiency):About3600PCS-4500PCSCells/H

12、标配点焊机:

MDA-8000B晶体管点焊电源,数量两台

Standard spot welding machine:

MDA-8000B Transistor spot welding power supply, 2 sets

Adaptive range: Power Battery series-parallel combination of batteries, multi-parallel multi-series combination, electric tool battery, torsion car battery (1 die spot welding 6 groups) , energy storage battery pack, Electric Bicycle Battery, etc.

适合电芯(battery range):14430/14500/18500/18650/21700

26650/26700/32050/32700

5、最大行程:X axis:200-600mm ; Y axis:200-400mm

6、适合点焊针:进口直径4-4*6平头焊针(凸点焊接使用)

进口直径1.7*100MM(焊点点焊)

Suitable for spot welding:

Imported 4-4 * 6 flat head Pin (for projection welding)

Inlet diameter 1.7 * 100MM (spot welding)

7、适合镍片宽度:成型镍片

Suitable for nickel sheet width : Shaped nickel sheet

8、可定制点焊模具前进后出型(适合自动生产线使用)

Can Be customized spot welding die forward and backward type (suitable for automatic production line)

9、可定制自动打磨焊针功能

The function of auto-grinding and welding needle can be customized

10、适合镍片厚度(Nickel sheet thickness):

0.1MM---0.2MM(0.15—0.2MM厚度镍片需开槽)

(0.15-0.2MM thickness nickel sheet needs to be slotted)

凸点焊镍片(Bump welding nickel sheet):0.21—0.4MM

11、生产效率(Efficiency):About3600PCS-4500PCSCells/H

12、标配点焊机:

MDA-8000B晶体管点焊电源,数量两台

Standard spot welding machine:

MDA-8000B Transistor spot welding power supply, 2 sets

13、 三种点焊数据输入Three kinds of data input for spot welding:

点阵输入法 Lattice input method

阵列输入法 Array input method

U盘导入法,把点焊数据储存到U盘,直接导入到机器,(U盘CAD数据按单次导入到触摸屏,然后可批量从触摸屏导出到U盘,再一次性到入到其他机器使用)

U Disk import method, the spot welding data stored to the U Disk, direct import to the machine, (U disk CAD data by a single import to the touch screen, and then can be bulk from the touch screen export to the U Disk, once again into other machines to use)

14、点焊模具型号命名:中英文输入

Type designation of spot welding die:Chinese and English input

15、控制器件:7.5寸触摸屏,6轴高速PLC编程器,3轴750W伺服电机,2轴400W伺服电机驱动电动焊头

Control device:7.5-inch touch screen, 6-axis high-speed PLC

programmer, 3-axis 750W servo motor, 2-axis 400W servo motor drive electric welding head

16、镍带采用成型镍带,减少浪费

The nickel strip adopts the shaped nickel strip to reduce the waste

17、设备调试简单,易学易懂,换型号速度快(0-199组数据可调用)

Equipment debugging is simple, easy to learn and understand, change models quickly (0-199 groups of data can be called)

18、焊头动力:伺服电动

Welding power:Servo motor

19、成品电池治具:出厂附带1套绝缘电木治具(2个)

Finished Battery fixture:Factory with 1 set of insulated bakelite fixture (2)

20、本公司产品保修期为贰年

The warranty period of our products is two years

21、设备外形尺寸(Size):L1630*W850*H1630MM

22、设备重量(Weight) :220KG

23、 设备主要配件清单(List of major accessories)

24、 点焊产品图片 Photo of spot welding product

设备优点

Advantages and disadvantages of equipment

● 设备采用铝合金加钣金结构方式,牢固,不易松动,确保定性

The equipment is made of aluminum alloy and sheetmetal structure, which is firm, not easy to loose and ensures the quality

● 适合于电池组的大批量自动化点焊

Suitable for automatic spot welding of large batch of battery pack

● 点焊效果稳定,有保障

The spot welding effect is stable and guaranteed

● 焊接效率高,以18650为例:约3600PCS-4000PCS电芯/小时

High welding efficiency, take 18650 as an example:

about 4000PCS-5000PCS Cells/H

● 点焊模具有防呆配置,普通员工可调试设备和操作设备

The spot welding die is equipped with anti-stuffiness device, which can be adjusted and operated by common staff

● 设备自带200套点焊参数储存,无限次U盘存储导入,可快速切换点焊型号

The equipment has 200 sets of spot welding parameter storage, unlimited time u disk storage import, can quickly switch spot welding model

● 设备电源要求,220V交流接入电源主线国标6平方电线,气源0.4-0.8Mpa无杂质,无水雾,以保障设备的稳定性

Equipment Power Requirements, 380V AC power supply main line 6 square national standard wire, gas source 0.4-0.8 MPA no

扫描微信咨询

扫描微信咨询